From time to time vendors advertise a discount off a high retail price (“Save 35 %!”), “free” windows or a lower price for shutter panels, only ($13.95/SF!). Like most industries, the shutter business has its share of overly enthusiastic marketers. Vendors sometimes over-price, then advertise “discounts” or “free” services or other “extras”. Watch out for hidden delivery fees tacked on, trick calculations, extra charges for installation or materials, or extra charges for “minimum order quantity”. By the time the shutters you wanted are delivered and installed, your bargain price may not be such a bargain.

Overall, shutters made in China are less expensive than American-made shutters, sometimes as much as one-third less (see below for a fuller discussion of both countries’ products.) And, as in many industries, manufacturers tend to be more price-competitive than wholesalers, and wholesalers tend to be more competitive than retailers. This can vary quite a bit, however, depending on the levels of services and selections offered.

We partnered with a local material supplier in Houston, TX that sells shutter components nationwide. By doing this we can offer American-made shutters directly to you for the same price a shutter distributor can sell you Chinese shutters. And since the shutters are manufactured in Houston, our customers are able to tour the facility to see how our products are made.

Both products have a market based on their strengths and weaknesses. Chinese shutter manufacturers have significant cost advantages based on their very low wage rates for workers and fewer government regulatory expenses. However, Chinese manufacturers are handicapped by their distance from the U.S. market. As a result, Chinese manufacturers have entered the U.S. market with more standardized products and an emphasis on lower prices over quality, selection, or service. Chinese product quality has improved over the last few years, but some products are available with unique frame styles. The Chinese shutters remain, for the most part, the least expensive shutters on the market, up to 25% less than American-made shutters.

American shutter manufacturers generally offer more customized products with better materials, more consistent quality, longer warranties, and faster delivery than offshore manufacturers. One of the reasons is that American manufacturers have a long history of domestic shutter production. The close proximity between the U.S. manufacturer and the U.S. consumer results in improved communication enables greater customization and reduces turnaround times. Issues relating to the environment, product disclosures, and product safety regulations set the U.S. apart from most lesser-developed countries.

Basswood is the strongest and lightest shutter material but tends to be the most expensive. Its qualities mean little or no sagging in the panels or louvers, attractive slimmer pieces with greater architectural integrity, and the opportunity for more elegant designs. Some manufacturers are switching to cedar, poplar, pine, or exotic hardwoods to decrease cost while maintaining most of the strength of basswood.

Engineered Wood: Consumers who like the look of wood, but are unable to afford traditional hardwoods can find similar looks in laminated, finger-jointed, and pressboard woods. These products are created by mixing and gluing wood pieces to provide straighter, less expensive material. However, these “engineered” woods tend to have issues with weight, inconsistent joinery, and glue that ages and wears differently than the adjoining wood. With time and wear, glued joints may flex differently creating surface cracks and dark glue marks.

Plastics can be made with color additives, injected with color additives, or made and then baked with a color coating. All plastics are produced in large batches making color choices limited and permanent. However, most plastics are less expensive than wood, and virtually all are waterproof.

Traditional extruded vinyl has the poorest weight-to-strength ratio and is the most likely to suffer from sagging, fading yellowing, ultra-violet, and heat-related damage. It is the least expensive of the plastics.

Vinyl with an aluminum core is an improvement with a better weight-to-strength ratio. It is less likely to sag and can be made into a wide variety of custom shapes.

Vinyl foam is the highest quality of plastic products. It is lighter and stronger than traditional vinyl and avoids most of the sun-related defects that can be found with vinyl. It is the most expensive of the plastics and may cost as much or more than basswood.

This is the material found beneath the “wood” decal in very inexpensive office furniture. It is no longer commonly used due to the defects inherent in the product. MDF is the weakest and heaviest of the shutter materials. It does not wear well but may be substantially cheaper than alternatives.

You know you are talking to a slick or misinformed salesperson if you hear one of the following:

Basswood is stronger and lighter than vinyl, MDF, and other shutter materials, so it is LESS likely to warp or sag than these materials. The likelihood of yellowing and chipping depends on the type of paint and undercoat used. Top-quality basswood is typically painted with acrylic or the best available waterborne paints. These are highly chip-resistant and much less likely to exhibit surface damage than most plastic or lower-quality painted products. Inexpensive vinyl products are the most likely to have surface issues including yellowing, fading, chipping, and sagging.

Both materials are cleaned the same way with a duster or damp cloth. Both materials are highly stain-resistant. Both materials will be damaged by fire, stains, and caustic materials.

Plastic shutters may build up a static charge that attracts dust. However, even without static, dust falls on all shutter materials at the same rate, and is removed the same way: with a duster or damp cloth.

Sandblasted wood, with its irregular, smooth surface tends to hide dust better than other surfaces but cleans up the same way.

This myth, though often repeated, confuses us the most. All of the available evidence – from hundreds of years of fine wood furniture to wood-framed houses, wood joists, wood beams, etc. – indicates that properly prepared and maintained wood does NOT warp. There may have been a time before kiln-dried lumber was popular, or when green wood was used, that warping would have occurred as the wood cured. However, that time is literally hundreds of years past. Based on the last 30 years of experience with kiln-dried Basswood we are confident in guaranteeing that, unless it is exposed to severe moisture, our wood will NEVER warp.

This is akin to saying a plastic picket fence corrals more bees than a wood one. The loss of cold or heat is between the pickets, not through the plastic or wood. As a practical matter, when any shutters are open, they don’t have much insulation value at all. When closed, they’re filled with gaps between louvers, gaps between panels and frames, and gaps between frames and the mounting surfaces. The best insulating shutter is the one with the narrowest gaps and the most accurate installation. A cheap shutter, even with the best installation, is likely to be a mediocre insulator, regardless of the materials used. Even a great shutter, if installed poorly, is a lousy insulator. High-quality, custom Basswood shutters, installed properly, tend to have the narrowest gaps and the best insulation available.

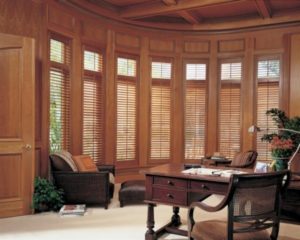

The most distinctive characteristics of the plantation in Houston’s Blindsandshutters.us shutters include the permanent frame around the window, and the shutter panel itself has moveable louvers inside 4 stationary sides.